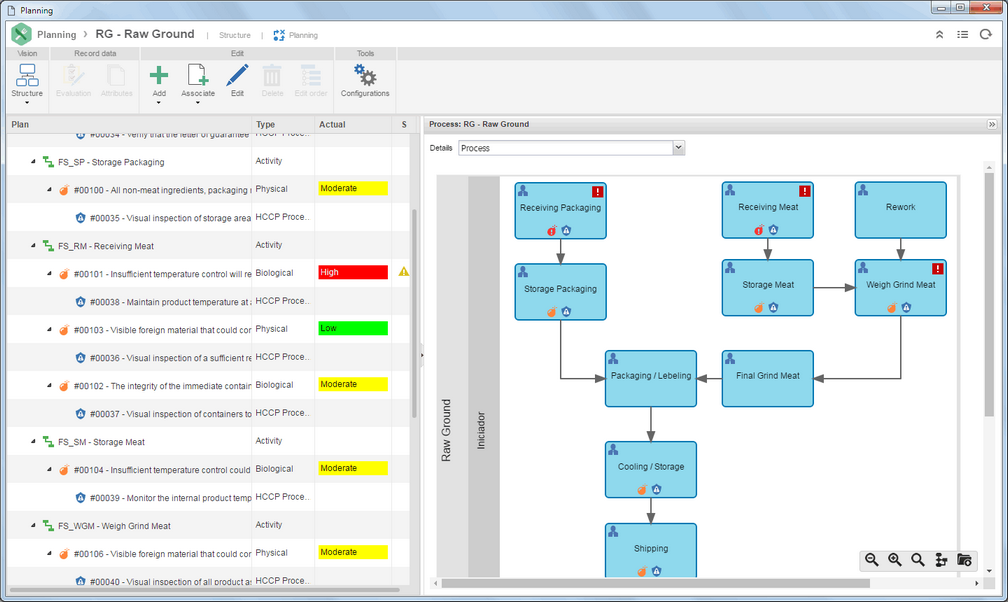

A new component was released in version 2.0.7, SE Food Safety. It aims at meeting the food safety needs, for example, meeting the HACCP. This component is internally linked with components SE Process, SE Risk, and SE PDM. The idea is to centralize all the food safety demands in a component specialist in that context. The component requirements are described according to the main HACCP steps.

Risk identification and analysis

The identification and analysis of risks are performed aiming at the following objectives:

▪To identify meaningful risks and characterize the corresponding preventive measures;

▪To edit a preparation step to ensure security, when necessary;

▪To serve as the base for the identification of critical control points (CCP).

All these operations may be performed on the Food Safety planning screen.

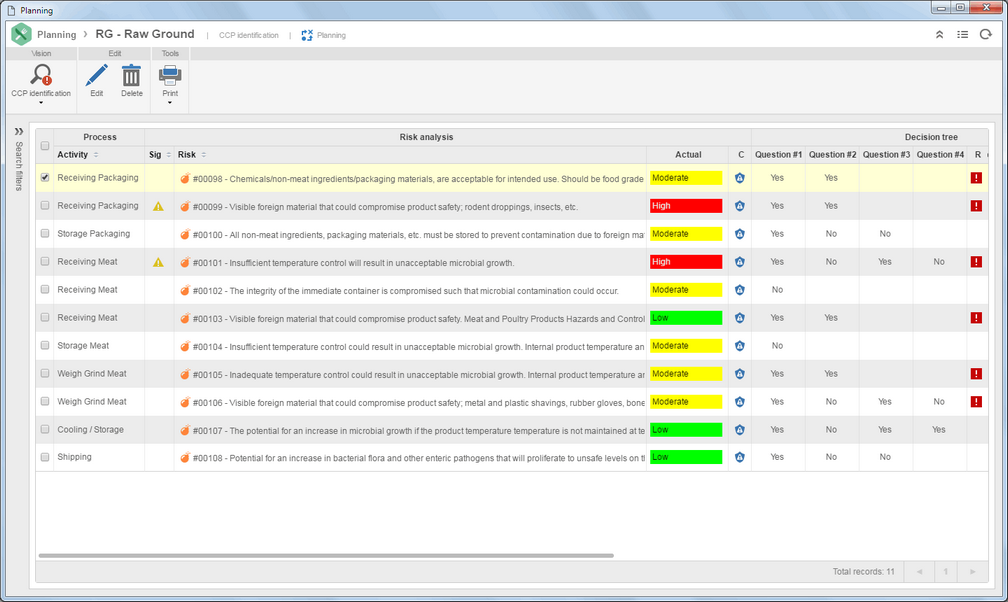

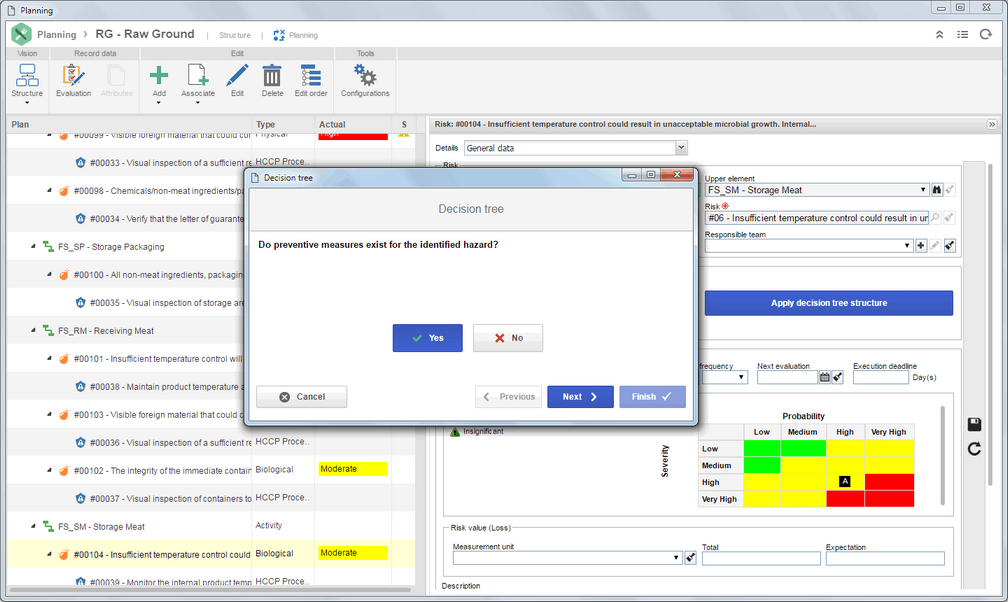

Determining Critical Control Points (CCP)

CCPs may be defined at any point, step, or procedure the control measures (preventive) apply to, with the objective of keeping a significant risk under control, to eliminate, prevent, or reduce the risks to the consumer health. The decision tree is used to determine the CCPs. The decision tree is totally flexible and configurable.

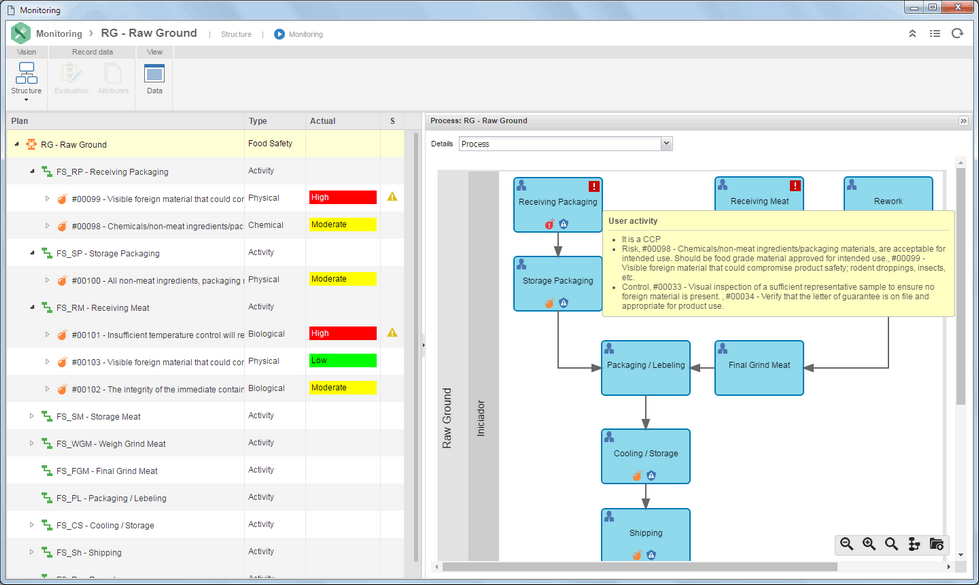

HACCP monitoring

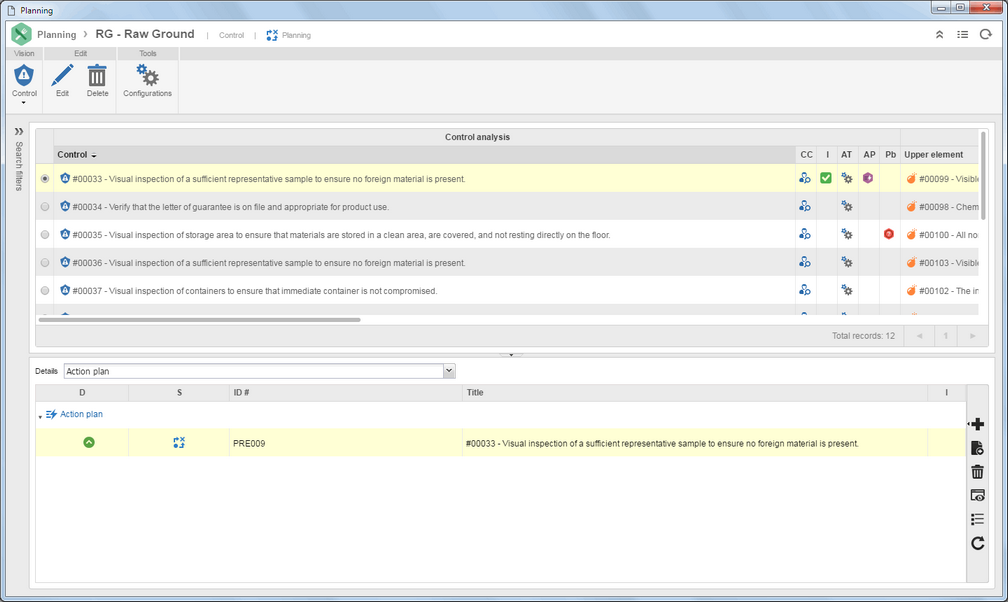

Monitoring is a planned sequence of observations or measurements to evaluate whether a determined risk is under control and to create a trustworthy record for future use in the verification. In the control vision of the food safety plan, it is possible to observe whether the risks are under control.

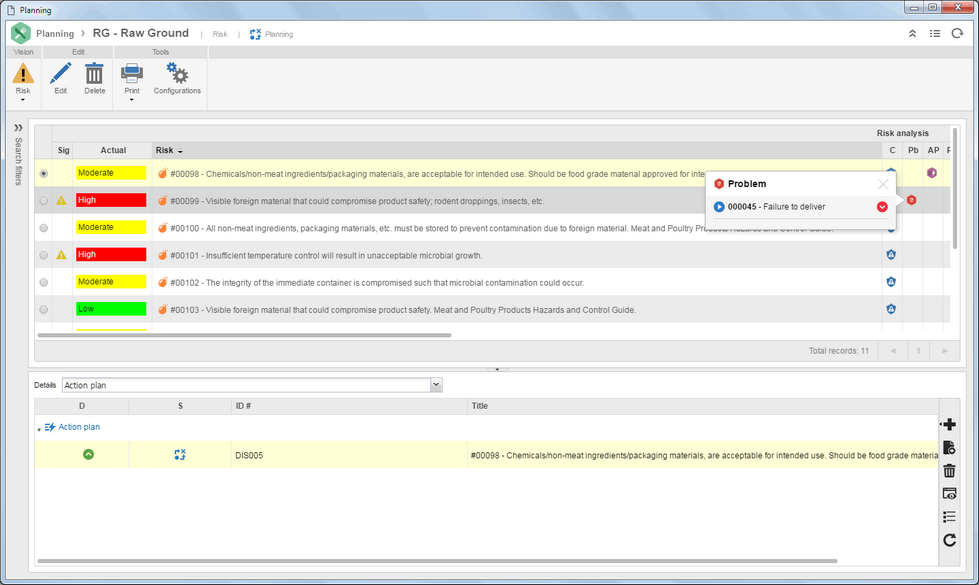

Measures/Corrective actions

Corrective actions must always be applied when there are deviations in the established critical limits. The HACCP plan must specify the procedure to be followed when the deviation occurs and the responsible for the corrective actions. Corrective actions must be created and there may be the need to increase the frequency of the CCP controls or even changes to the process. In the system, it is possible to create corrective actions as Action plan, Incidents, Problems, or Workflow.

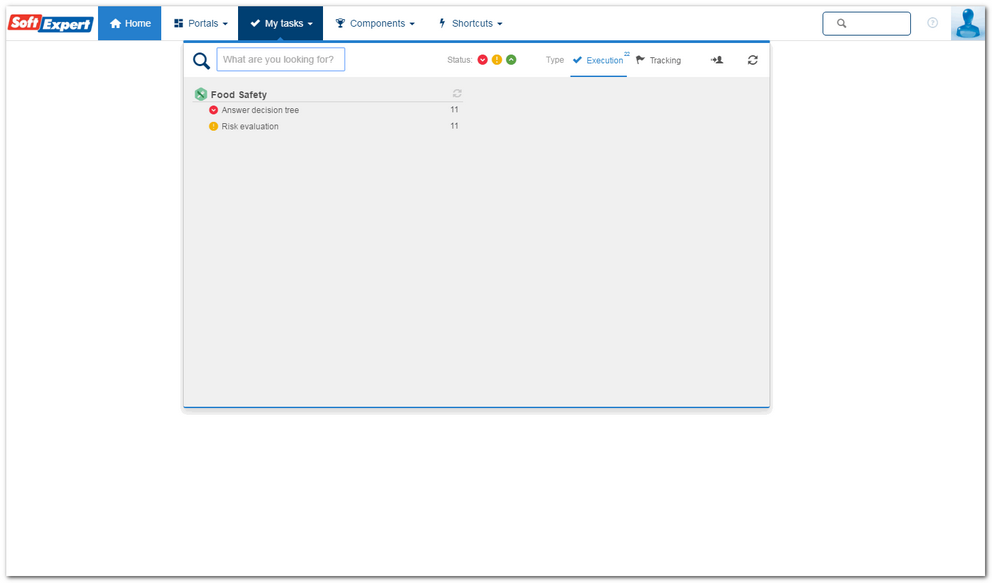

Food safety plan verification

The verification consists in the use of procedures in addition to those used in the monitoring to bring evidence about whether the HACCP system is working correctly. The verification may be executed through the Food safety plan execution screen, available either in the Tasks or the Portal.

Record and documentation

After creating the food safety plan, the record step is where it is possible to verify the system information. All data and information obtained during the planning must be saved and duly standardized for each establishment. To meet this step, the system has the monitoring, view, and vision screens, which may be made available in the Portal.